KYLIN-780

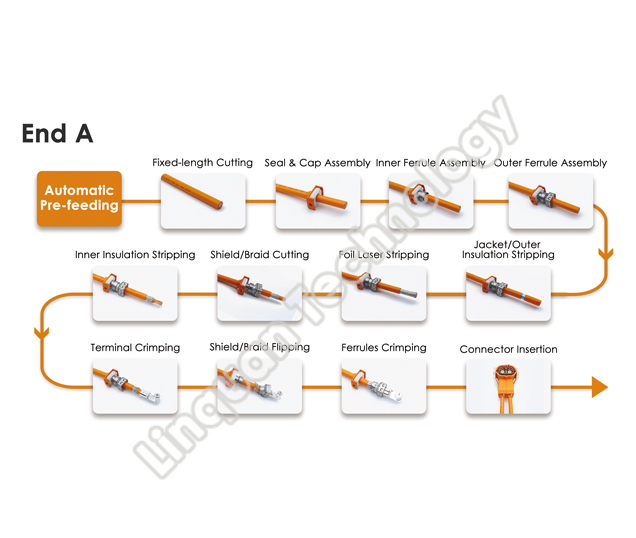

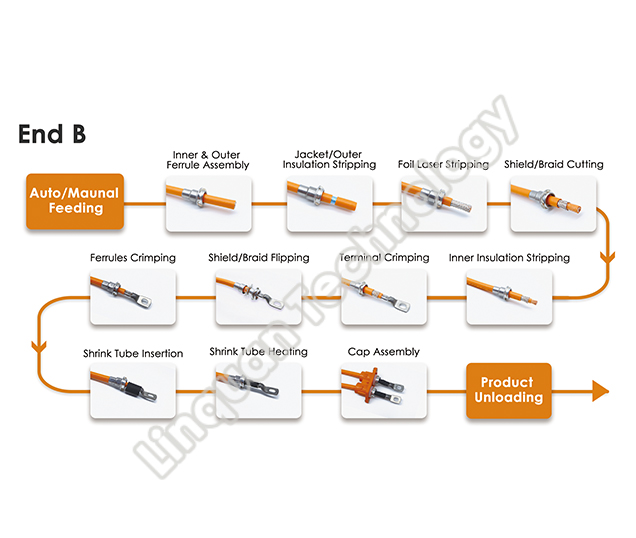

Flexible modular configuration creates a platform for multiple processing stations integration. Kylin series machine could fulfill functions of cable pre-feeding, inner/outer insulation stripping, terminal crimping, ferrules assembly & crimping, foil stripping, shield cutting/flipping, seal & caps assembly and connector insertion based on HV cable harness processing requirements.

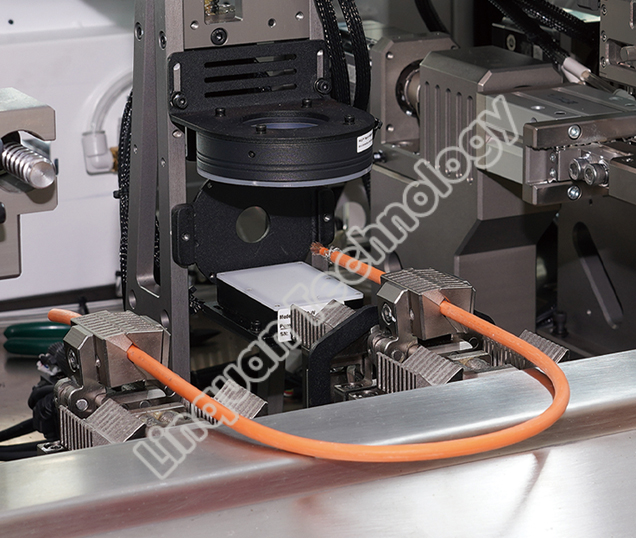

PLC control system and the full servo motor drive mechanical structure. Ultra precision, adjustable smallest unit to 0.01mm.

Humanization HMI design. Extensive database for saving multiple product processing parameters. Easy changeover by switching the saved product code. All modular functional station and QC devices parameters are integrated within one system. Commissioning & operating friendly.

Every machine loaded with Linquan signature self-developed CFM (Crimping force monitoring) and CCD visual inspection system. Real-time monitoring each producing process. Ensuring machine’s stable performance while keeping incredible PPH.

Technical Parameters

| Cable Cross-section | 16mm²-120mm² | Cutting Length | 600-3500mm(can be customized) |

| PPH | 18 sec per single-sided loading/200pcs/hr (Piece output depends on module combinations) | Efficiency | 200pcs/hr (Depends on different producing process and the functional module quantity, productivity is different) |

| Power Source | China - 380V/3 Phase/50Hz Canada - 600V/3 Phase/60Hz USA/Japan - 480V/3 Phase/60Hz Mexico/Honduras - 480V/3 Phase/60Hz Europe - 400V/3 Phase/50Hz | Compressed Air Connection | 0.5Mpa-0.7Mpa |

| Jacket Stripping Length | 0-60mm, stripping precision ±0.5mm can be full stripping and half stripping | Foil Stripping Length | 3-50mm, cutting precision ±1mm |

| Shield Cutting Length | 5-55mm, cutting accuracy ±0.4mm | Shield Flipping | 5-20mm, 90-180 degree |

| Insulation Stripping Length | 0-55mm, stripping precision ±0.5mm can be full stripping and half stripping | Crimping Capacity | 15KN |

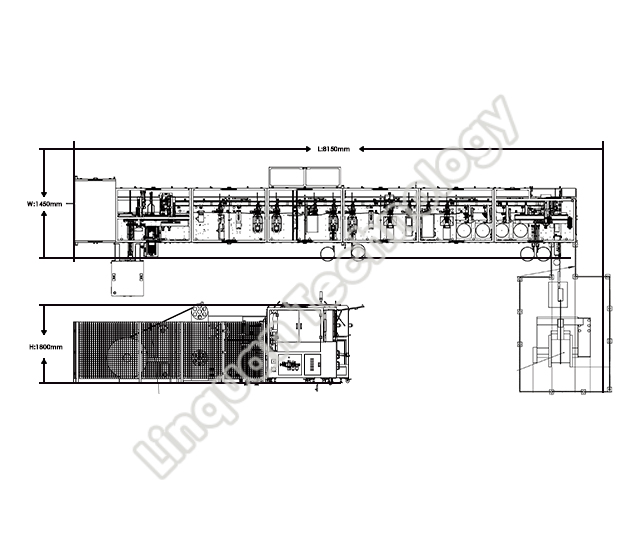

| Weight | 3000KG | Equipment Size | L8150*W1450*H1800mm |

| Crimping Module | 10 ton presser for terminal crimping 15 ton presser for ferrules crimping | Process Monitoring (integrated) | CCD (cutting/stripping/crimping) Crimping Force Monitoring |

| Function | Pre-feeding, Feeding and cutting, Inner/Outer ferrule assembly, Ferrules crimping, Outer/Innser insulation stripping, Foil stripping, Shield cutting/flipping, Terminal crimping, Connector insertion, Seal & Cap assembly, Spot taping, Shrink tube insertion & heating |

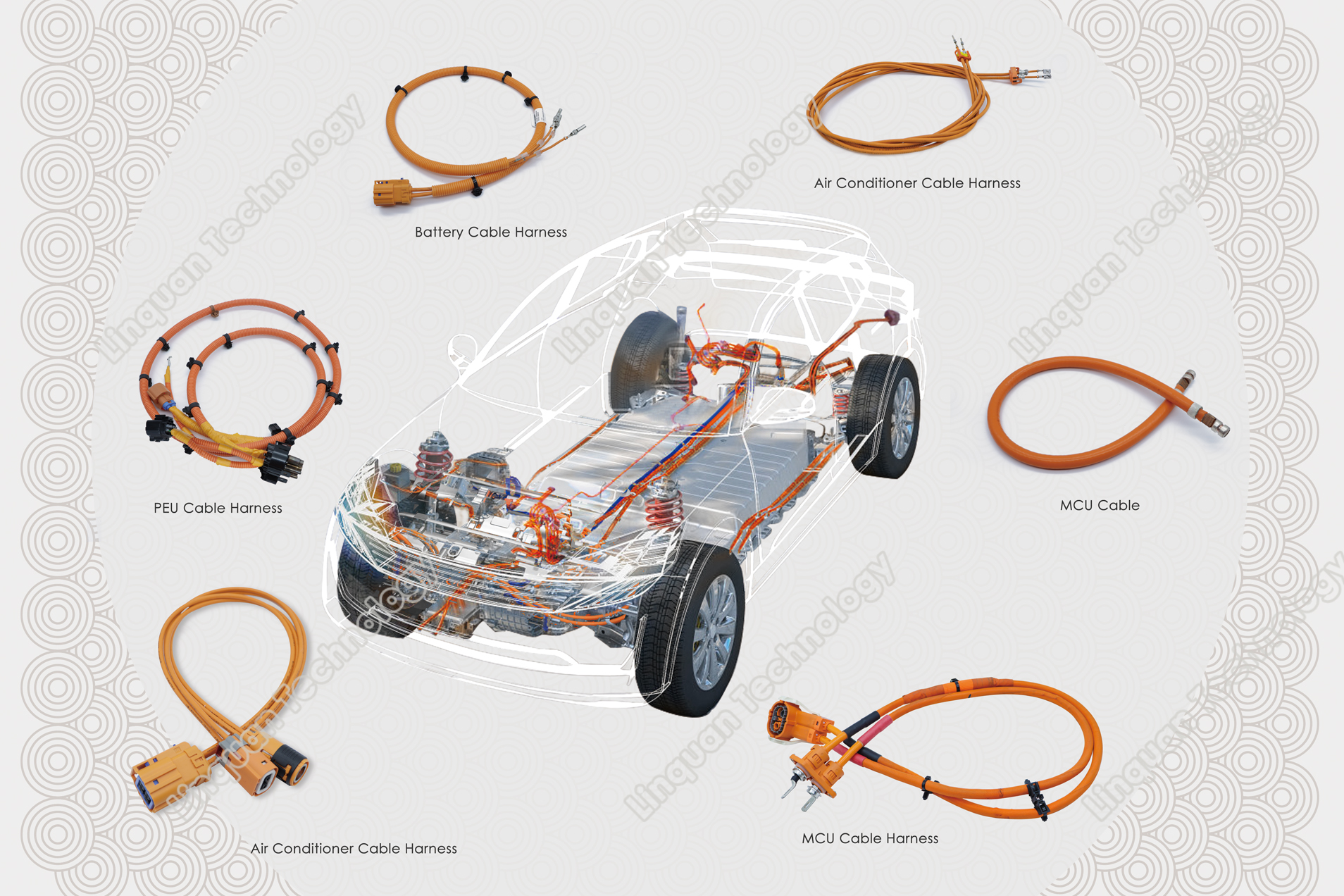

EV / HEV / PHEV HIGH VOLTAGE CABLE HARNESSES

FAMILY MEMBERS OF KYLIN

KYLIN-780

16-120mm² HV Cable Harness Manufacturing

KYLIN-770

2.5-16mm² HV Cable Harness Manufacturing

KYLIN-760

Small For HV Cable Seal Application, Insulation Stripping, Terminal Crimping

KYLIN-750/740

For HV Cable Outer/Inner Insulation Stripping, Shield Cutting, Shield Flipping

Linquan KYLIN-770/780 platform is specially designed for HV cable harness manufacturing. Wide applicable for versatile HV cable harnesses such as HEV/EV, HEV/EV charger/PDU, AC/DC inlet, power battery, Motor Controller, etc.

Flexible modular configuration creates a platform for multiple processing stations integration. Kylin-770/780 platform could fulfill functions of cable pre-feeding, fixed-length cutting, inner/outer insulation stripping, ferrules assembly, ferrules crimping, foil stripping, shield cutting/flipping, terminal crimping, caps & seal assembly, connector insertion, shrink tube insertion & heating and taping based on HV cable harness processing requirements. Meanwhile, the platform loaded with Linquan self-developed powerful CCD visual inspection & CFM QC systems to real-time monitoring scraps.

KYLIN-770/780 platforms are intended to provide best fully automatic scenario on HV cable processing, which make manufacturing productivity significantly optimized and improved.

Cable Feeding Module

Integrated HMI operation platform.

Individually manufacturing parameters saving. Easy & quick changeover for versatile cross section cable processing.

CCD Visual Inspection

(TDVM-1)

Integrated QC module, efficient quality monitoring.

Triple prism inspection design 360° seamless observation.

Real-time monitoring producing process.

In time detecting scraps.

Cloud storage for over 6 years’ inspection pictures.

Remarkable data traceability.